Lead Screws#

Lead screws use a threaded rod to create high-torque linear motion. Their primary advantage is being able to handle much higher loads than other unmodified kit options. While this option was popularized in Rover Ruckus for hanging robots, variations have been in use since as far back as Res-Q. Another use case for lead screws is to change the angle of an arm platform, though this is more common in FRC®. However, this ability to handle high loads comes at a cost: lead screws are extremely slow.

By far the most popular lead screw option is the ServoCity Linear Actuator kit. Overall, this kit is lightweight, simple, and cheap. It can be a good start for teams using REV and needing a linear extension, and is generally usable out of the box.

Advantages#

Easy way for high-load, high-torque applications

Compact form factor

Typically only requires one motor

Disadvantages#

Not for quick linear extensions

High torque translates to slow extension speed

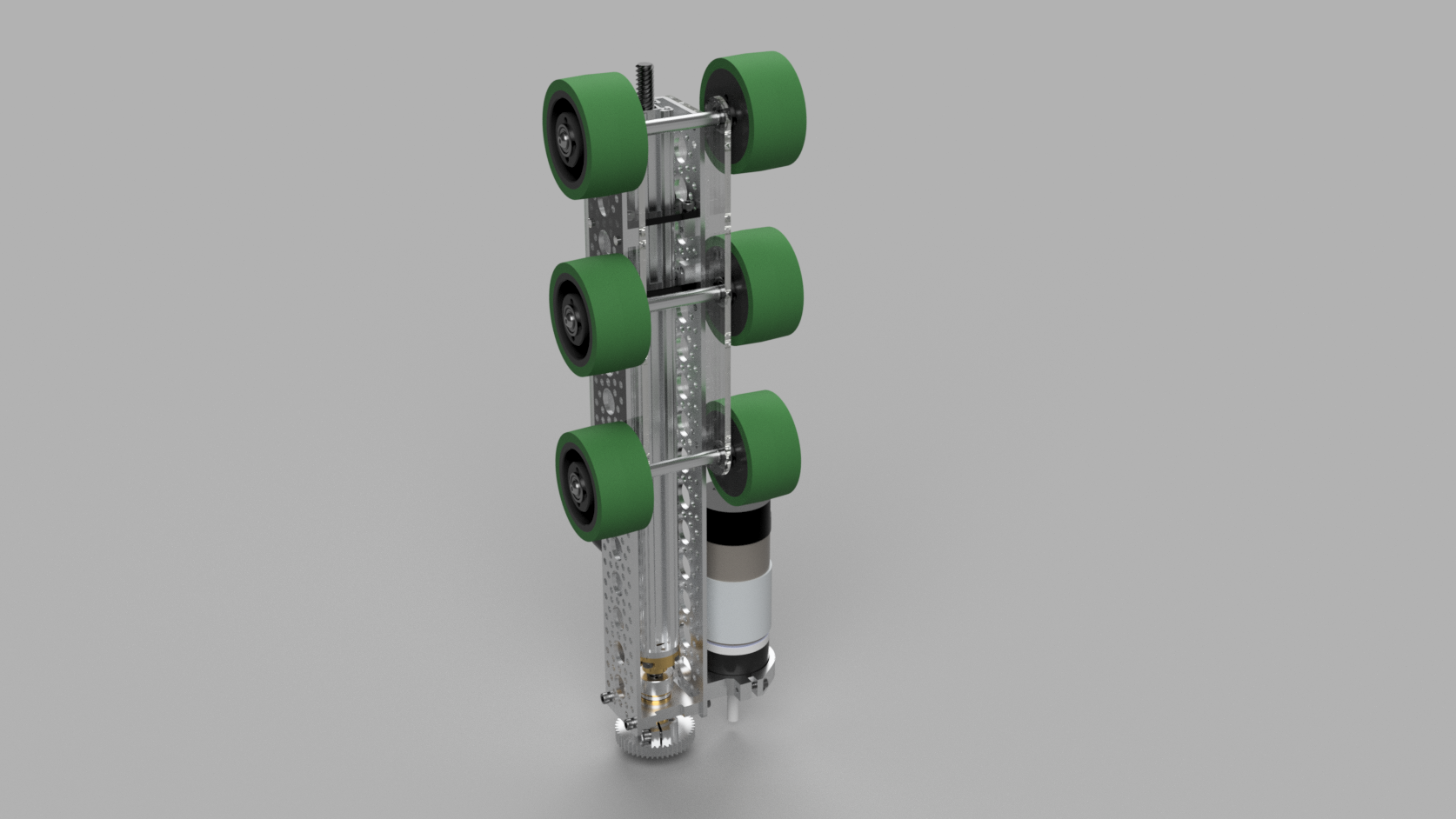

11115 Gluten Free, Rover Ruckus, Actobotics lead screw used for hang#